Tholen - Instead of waiting several weeks, get insight into the germination of seed within a few days, and then save on labour as well. With a new seed scanner, Sendot has a nice piece of automation to offer to breeding companies, but also to plant breeders and growers who want to know what kind of seed they have.

On Wednesday 24 May, the first installation was delivered to a Dutch plant grower. In Houten at the sensor manufacturer's headquarters, they expect this to be the starting signal for many more installations, made possible by serial production.

For the entire chain

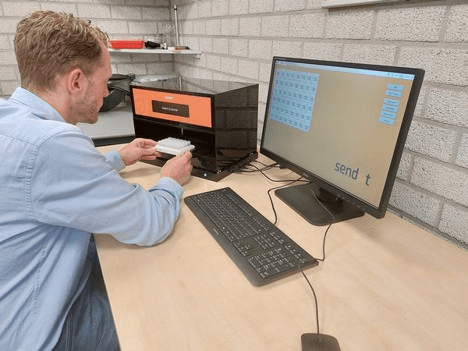

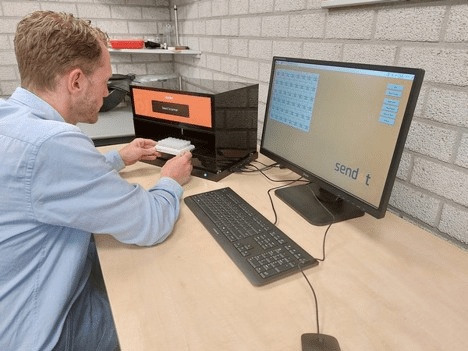

Measuring germination is not new. What is new is that Sendot has developed a scanner that is compact and therefore easy to use. Don't expect a huge cabinet, but a robot that can be taken from greenhouse to greenhouse under the arm, so to speak. “We assume that once companies get used to our technology, they will quickly purchase several scanners,” say Bert van Tol and Arie Draaijer, CEO and CTO of Sendot.

“Indeed, what we want to achieve is to enable quality assurance throughout the chain,” adds Commercial Manager Erwin Gräfe. Making sensors available to the entire chain, not just to science and laboratories, is what the company stands for. “This is why our products must be low-threshold and easy to use.”

Follow germination

Sendot provides a robot, but not insignificantly, also software, which allows easy and clear data reading, and analysis in graphs. Bert shows an example graph analysing the germination of tomato seeds. This germination capacity is determined by the oxygen consumption of the seed in the first phase of germination.

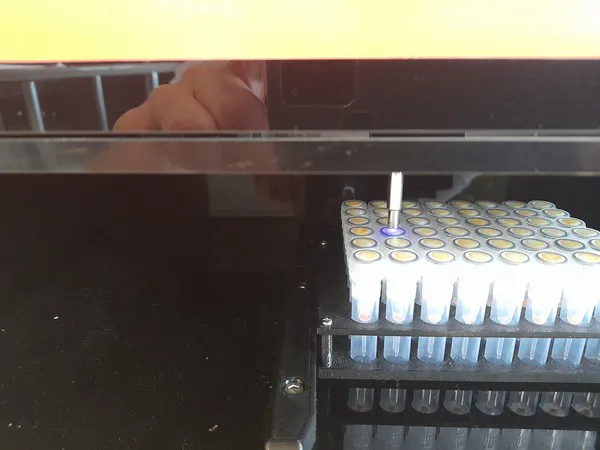

In the graph, you can see this in different coloured lines, one colour per seed. Not much happens in the first few hours. The seed first gets wet from the liquid it is in. The line starts at 21%, the percentage of oxygen in the air. Once wet, germination begins. Then the seed also starts using oxygen. Sendot can measure that. They do so using a special, self-developed (literally baked) coating at the top of the tube.

Knowing quality quickly

There is variation in how individual seeds germinate. Seed suppliers do their best to deliver seeds with as even a germination as possible. Moreover, they promise a percentage of emergence on delivery. However, it can happen that seeds, for example if they are already older, have less germination. A small test with the seed scanner can reveal this.

Why this is useful? For example, when sowing at a plant breeder, to sow enough, taking into account a percentage of seeds that do not sprout. There is nothing more annoying than finding out after, say, two weeks, at germination, that some of the seeds do not germinate. Anyone who then has to sow an extra batch is falling behind.

Seed treatment

The scanner can also be of great use when evaluating seed treatment. Arie: “The landscape of substance use is changing rapidly, less and less is allowed and the use of biological alternatives is still in its infancy. With the seed scanner, rapid and automated evaluation is possible. This means fewer standard germination tests are needed.”

Prototype

Anyone thinking, hey, that scanner, I've seen that before, may be right. A prototype is already in use at a Dutch grower. Meanwhile, Sendot is ready to start serial production. A 3D printer is running in Houten.

Those not yet familiar with the seed scanner may already be familiar with Sendot's various other sensors. “Our photosynthesis sensor is going very fast at the moment,” Erwin points out. “But we also have, for example, an oxygen sensor, which measures temperature and oxygen in the root environment.” Here, a similar coating has been used as also in the seed scanner for germination, only the coating has been deployed in a different way, on the tip of the mobile sensor.

Easier than with human eye

From the curves of the graphs made with the data from the seed scanner, which can be seen on the screen that the user connects to the seed scanner with a connector, other derivatives besides germination can be extracted, Bert explains. For example, one line in the example can be noticed to drop harder than others, or much earlier than other lines. Those seeds start germinating later. If the line drops hard, then the seed is very germinative. “Such things are difficult to measure in manual germination analysis,” the CEO points out. “It can be done, by measuring leaf area, but that is quite difficult, especially with all those small leaves.”

Moreover, the robot can do it quickly. The robot can process one plate, or actually a rack, of tubes per minute. How many seeds are in it varies. The robot can handle 48, i.e. 48 tubes, or 96 at a time. “These are numbers that suit current practice,” Bert points out. If the seeds are very large, less is also possible. 24 tubes, for example. In time, Sendot is also looking at robotics for changing the plates. “Then you won't be able to score against them at all,” he says.”

To measure sperm quality, Sendot also already has a mobile sensor available that measures chlorophyll. Together with the seed scanner, users can get even more data on seed quality themselves.